0%

distortion of the balast bed.

distortion of the balast bed.

RSS and its Italian distributor Thermit Italia have successfully supplied the first magnetic safety barriers that have been specifically designed to prevent passengers crossing railway tracks. The fast assembly and dismantling of the RSS safety barriers maximizes the flexibility in selecting designated areas for protection purposes.

Rail Safety Systems BV and TPA completed a Switch Crossing Safety Barrier demonstration at Stoke on Trent in England for several Clients, on the 17th and 18th of August 2017.RSS and TPA demonstrated to several companies how to build our Magnetically Attached Switch Crossing Safety Barrier over a railway crossing in less than 15 minutes with only 2 persons. Due to this unique world patented system, it is now possible to build a safety barrier across a switch/crossing in several minutes and continue seamlessly with existing Magnetically Attached Safety Barrier to protect the health of the workforce from Silica Dusts and physically from moving vehicles such as Trains and RRV’s. Removal of the system will take even less time.

Watch te video on te left.

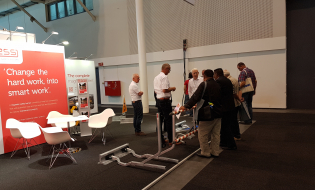

RSS was present at IAF, the International Exhibition on Track Technology, which was held in Münster from May 30-June 1.

IAF is by far the largest fair in the world in the field of track technology. With RSS innovative solution by using magnetic safety fences system we have been able to demonstrate the product for our many prospects and customers at our booth. Our most recent development is the possibility of having signs, such as TSR boards, or “Langsamfahrsignale” in Germany attached to the track with a RSS magnetic possibility has also been received with great interest. In Germany we expect the homologation before yearend, following the UK where the first sales have already been completed.

For more info please contact our office.

RSS was present, in close cooperation with its UK distributor Innovative Railway Safety Ltd, on the Railtex 2017 at NEC Birmingham on May 9-11. Railtex is the all-encompassing showcase for technological innovations across the entire rail supply market. With the RSS stand strategically located , we were able to demonstrate our magnetic safety barriers next to our innovative solutions for TSR boards and signs.

It was possible to meet and greet many of our customers and prospects and their enthusiasm confirmed that our presence was not only appreciated but also successful!

1500 meters RSS Magnetic Safety Fences protect the workers on project Luxembourg-Sandweiler. The project was carried out by a co-operation of 4 Luxembourg contractors i.e., Lux TP, Perrard, Baatz and Tralux. The RSS Magnetic Safety Barrier was supplied by Heli Equipment Belgium.

Rail Safety Systems BV (RSS) was crowned the winner of the Institution of Occupational Safety and Health’s (IOSH) International Railway Group Award 2016, in recognition of its work to create a new magnetically-attached safety barrier. This highly innovative product makes the removal of the ballast beneath the rail track redundant and significantly contributes to eliminating potential health hazards for railway workers. Paul Scapens (second left), managing director of Innovative Railway Safety Ltd. and exclusive distributor of RSS in Great Britain with on his right Jan Bakker, CEO of RSS, receives the IOSH International Railway Group Award 2016 from IOSH president Graham Parker (left), and Keith Morey, Chair of the IOSH Railway Group.

These images are taken at Roma Termini Railway station. In this special environment the RSS magnetic fences are not used to protect railway workers, but they prevent the crossing of the railway track by passengers who do not understand the risk of being killed by a train passing by!

1.200 meters of RSS magnetic fences protect the working area on a RFI large renewal project of the railway Udine – Tarvisio nearby Carnia Station. The Main Contractor is GCF, one of the top customers of Thermit Italiana. The reliable fast installation and dis-installation allows the customer to safely protect the working area easily moving the fence accordingly with the progress of the works.

1.200 metri di barriere protezione cantiere RSS con attacco magnetico alla rotaia proteggono l’area di lavoro in un importante progetto di rinnovamento di Rete Ferroviaria Italiana sulla linea Udine – Tarvisio, nelle vicinanze della stazione di Carnia. L’impresa responsabile dei lavori è la GCF, uno dei principali clienti della Thermit Italiana. L’affidabilità e velocità di installazione e disinstallazione consentono al cliente di mettere in sicurezza l’area di lavoro spostando agevolmente le barriere così da seguire l’avanzamento del cantiere.

With over 40,000 visitors, MATEXPO is Europe’s third largest trade fair with a focus on building equipment. RSS is proudly showcasing the Magnetic Rail Safety System at this established expo. Similar to all great design, simplicity has been built into our safety barriers. Fast assembly with only two components makes it a truly innovative product for railway maintenance.

Watch our video to see just how easy our safety barrier system works.

RSS fences, in collaboration with SOLYTEK, have been homologated by SNCF under n°DPI 14264. These fences have been adapted to SNCF requirement and can be used as defensive version by adding a panel with net developed by SOLYTEK. A 3 years contract have been signed with SNCF under N° CTR00050806

Our safety system as a prime example for the preservation of railway traffic during maintenance of the railway. See the whole article.

Since September 2014, nine ÖBB sites of engineering work have been using the magnetically attached safety barrier. The new barriers are used along stretches of engineering work on single or multiple track lines. The use has thus far proven to be completely effective and is highly praised by employees.

After a number of years of investments Deutsche Bahn awarded RSS with a long term distribution contract to be nominated for the exclusive supply of its patented magnetic based safety barrier system. Many years have been spent at research and testing, not only internally at DB but also by external companies such as TÜV to be absolutely convinced the system is meeting the high quality standards of DB and at the same time achieving significant cost reductions in easy and fast fitting or removal of the safety barrier system. RSS is proud to be awarded with this long term commitment and the nomination as strategic supplier.

At the Innotrans 2014 in Berlin a distribution agreement has been signed for the exclusive sales of the RSS innovative magnetic based safety barrier system. The Goldschmidt Thermit Group is the recognized and proven supplier worldwide for products and services for the construction, renovation, maintenance and modernization of railway tracks. In addition to RSS being active in the main European markets, the Group will further enhance the availability of the magnetic barrier system on a worldwide scale. The CEO’s of both the Goldschmidt Thermit Group and Rail Safety Systems announced at the Innotrans 2014 the importance of this strategic alliance. The German based company emphasized that the combination of the RSS innovative system with GT’s worldwide distribution power is an important step in achieving its mission to do everything better, to improve existing processes and develop new ones. Again an important milestone in RSS rapid market expansion.

This innovative new concept from RSS in the Netherlands uses

magnets to attach the safety barrier directly to the web of the

rail.

Safety barriers are used to protect rail track

workers from moving trains on the parallel track. Safety barriers are

the safest way to protect the health and safety of railroad workers, but

due to a variety of circumstances traditional safety barriers cannot

always be used. Erection of traditional barriers is time consuming as

they require removal of the ballast from under the rail. Similarly on

removal of the barrier, the ballast has to be re-instated and tamped

correctly. Unfortunately due to the above mentioned reasons safety

barriers are not always used, and we know that this can lead to

incidents, even fatal ones.

The TÜV tested RSS safety barrier

with magnet has received approval by the Deutsche Bahn and offers many

additional benefits to the fundamental one of protecting railway

workers.

Tests done in the UK by Network Rail, (who incidentally

have also fully tested and approved the system for UK rail

infrastructure PA05 05085) with a gang of 5 operators showed that it is

possible to erect 100 meters of RSS safety barrier in 15 minutes,

dismantling took 11 minutes – because there is no need to remove

or re-instate ballast. It took 2 hours with a gang of 10 people to

erect and dismantle 100 meters of conventional safety fencing, because

of the need to remove and re-instate the ballast.

Benefits

The

distinct advantages of the system are:

We are very proud to announce that Rail Safety Systems, after a year

of extensive testing, finally has obtained the TÜV approval

certificate for our magnetic mounted safety fence to protect

railway workers! Besides our European Approval (EN 13374) and the

winning of the Innovation award during Railtech 2011 this

is probably the most important highlight of the year for RSS.

The

TÜV approval is an absolute must to be successful in Germany. It

also will open other markets in and outside Europe, because TÜV is also

recognized there as a standard for safety andquality.

The Energlyn project in Caerphilly South Wales is a joint venture

between Morgan Sindall and Colas Rail. Having seen a demonstration of

the RSS Magnetically attached Safety Barrier by Innovative Railway

Safety Ltd of Swansea, it was decided that this innovative solution to

workforce protection, together with the obvious time and cost saving

implications, should be trialled for the benefit of the railway

infrastructure in Wales and the Western Region.

Tim

Thorne, Project Manager for Morgan Sindall decided following a brief

training session by IRS to replace the existing conventional barrier

with the Network Rail approved RSS Safety Barrier. His comments are as

follows: “We placed one operative, on one midweek line

block shift, with the task of taking down the 100m of Vortok fencing

that we had in place, and replacing it with the same length of

magnetic safety fence. Taking down the Vortok and reinstating the

ballast took several hours (considerably less, it should be noted,

than installation would have taken one man). Installing the magnetic

safety fence took 20 minutes. And with no disruption to the ballast

under the rails. The efficiency gain is there to see and all

operatives have been comfortable working and walking behind the

fence line.”

Network Rail IP Western division have kindly sponsored the

development and trial of the innovative RSS magnetically Attached TSR

Board (Temporary Speed Restriction Board). The final part of the trial

took place in a ‘live’ situation at Tumpy Green Lane,

Dursley, Gloucestershire, courtesy of Network Rail and Balfour Beatty

Rail.

As you can see in the video, no ballast was

required to be removed or replaced, and so the installation and removal

of the TSR Board was completed by one man in a 5minute ‘line

blockage’, rather than taking a ‘full possession’ with

a gang of 5 operatives, saving both time and expense. Initially

the sign was twice the size of a conventional TSR sign to give it

maximum exposure to the forces (air turbulence) created by the train

movement through the air, and ‘black bagged’ to avoid any

potential for confusion of train drivers. A Passenger Train at 80

km/h was passed by the TSR Sign initially, followed by the NR Track

measurement Train, a Passenger Train travelling at 160 km/h and then a

freight train at 120 km/h. As you can see from the video, there was no

visible movement or impact on the TSR Board. It remained firmly in

position despite being twice the size of a conventional sign and

therefore subject to greater loadings.

The trial was deemed an

unqualified success and the completed RSS Magnetically Attached TSR

Board is progressing to full approval by Network Rail.

We think that the positive, unqualified approval of the Rail Live Event at Stratford by all those taking part and/or attending was justified and wish to take this opportunity of thanking all those Network Rail Staff involved with its organisation. From our perspective, we were able to demonstrate the range of new products: all developed to improve safety, save time and expense; that we have developed since the inaugural approval by Network Rail of our RSS Magnetically Attached Safety Barrier.

Secondly with the co-operation of the NR Electrification demonstration

team, we were able to demonstrate in a live situation, that 4 men could

erect 50m of Safety Barrier in 5 minutes and dismantle it in 4 minutes

without disturbing the ballast, or incurring the costs associated with a

full-possession. It certainly impressed the crowd watching,

many of whom had not seen the RSS Magnetically Attached Safety Barrier

previously, and were initially sceptical of our claims that “5

operatives could erect 102 m of Safety Barrier in 15 minutes”

– seeing is believing!

Benefits of the Magnetically

Attached Safety Barrier

faster than some traditional safety system!

tools needed!

The Big Oxmox advised her not to do so, because there were thousands of bad Commas, wild Question Marks and devious Semikoli, but the Little Blind Text didn’t listen. She packed her seven versalia, put her initial into the belt and made herself on the way. When she reached the first hills of the Italic Mountains, she had a last view back on the skyline of her hometown Bookmarksgrove, the headline of Alphabet Village and the subline of her own road, the Line Lane. Pityful a rethoric question ran over her cheek, then